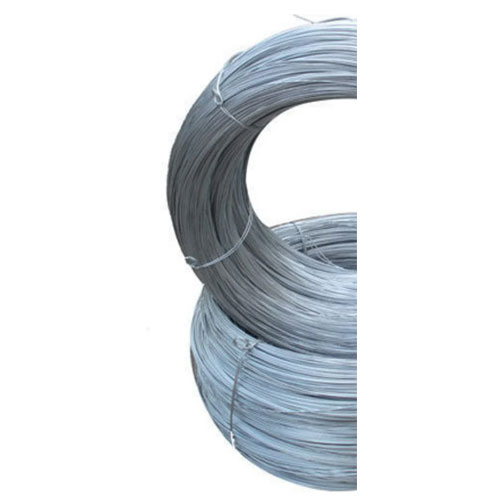

GI Conductor Rolls

PVC Coated Chain Link Fencing Manufacturer In Delhi

Product Details

Elevate Security with Concertina Wire Fencing in Delhi, India

Welcome to the forefront of security solutions with Concertina Wire Fencing, proudly manufactured and supplied by trusted industry leaders in Delhi. Our Concertina Fencing Wires stand as a robust deterrent, recognized for their efficacy in thwarting unwanted entries, be it from intruders or animals.

Crafted with precision, our Concertina Fencing Wire features sharp blades and a spiral wire structure, creating an impenetrable barrier along boundary walls. Anyone attempting to breach the perimeter is effectively trapped, ensuring enhanced security for your space.

Innovatively designed, our Concertina Wire Fencing seamlessly combines concertina coil wire with chain link fencing or diamond welded wire mesh. This unique blend not only fortifies your boundaries but also ensures safety without causing harm.

This versatile fencing solution finds its application in various settings, including prison boundaries, airport perimeters, residential areas, and government/commercial spaces. Its adaptability makes it a top choice for those seeking effective security measures.

Explore the different types of Concertina Fencing Wire, from those fastened to steel structures to those installed independently. Invest in security that goes beyond conventional measures – choose Concertina Wire Fencing for a safe and fortified environment.

Secure your space with the best prices and quality in Delhi, India. Contact us today to explore the diverse range of Concertina Fencing Wire solutions tailored to your security needs.”

Concertina Wires: A Comprehensive Guide

Welcome to our esteemed GI Conductor Wire manufacturing and supplying services in New Delhi, where we take pride in offering a diverse range that caters to various needs. Our GI Conductor Wires are meticulously crafted by twisting 7 strands of high-quality galvanized iron wire, ensuring optimal performance and durability.

In addition to standard lengths, we provide the flexibility to deliver GI Conductor Wires in customized lengths based on your specific requirements. These wires are specifically designed to offer robust support to poles, making them an ideal choice for various applications.

DO YOU NEED MORE INFORMATION?

GI Conductor Rolls Category

APPLICATION AREAS

Residential Fencing

Commercial Fencing

Residential Fencing

Construction Fencing

Industrial Fencing

Schools Fencing

Agricultural Fencing

Gardens Fencing

Defence Military Fencing

Airports & Roads Fencing

Sports Fencing

Parks & Gardens Fencing

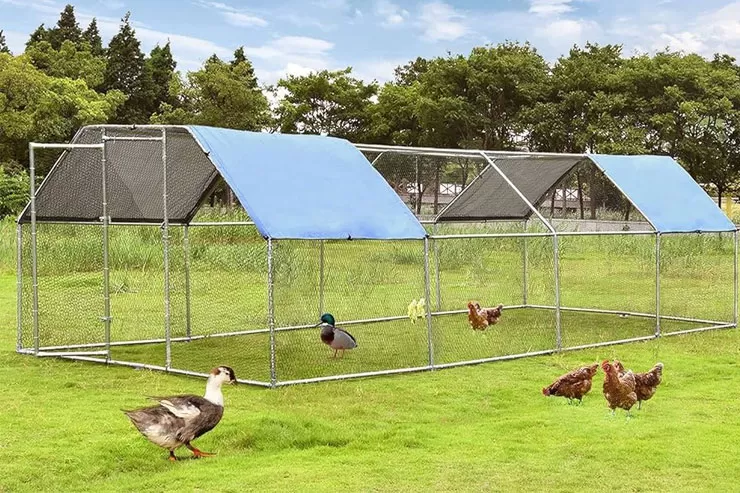

Poultry Fencing Wire

Wildlife Fencing Wire

College & University Fencing

Manufacturing Unit Fencing

Infrastructure and Transport Fencing

Farm, Gates, Outdoor & Garden Fencing Wire

Some of Our Major Clients